|

|

Saturday, June 21st, 2003

I started taking measurements for the window seat I am planning to build in our sitting room's bay window. I have pretty well in mind what the thing should look like at the end, what I mainly need to do is take the measurements from the space. I have linked to the images as separate files because they are big, and I don't know how to reduce them. Here is a floor plan and front elevation: layout.jpg The height of the seat (which you can't see because my scanner clipped it off) is 16"; I measured that height from a chair that feels comfortable. That is also good because it is a little over an inch short of the bottoms of the window sill moldings which will be above the seat. (I didn't draw the windows in to this plan but there are three of them, in the places you would expect them to be.) So, good: the length of the seat will be 94", and the width -- oh, now I see my scanner trimmed that off too -- the depth of the bay window is 36", and the depth of the part that is 94" wide is 14"; so I am thinking 32" is a good width for my seat. At 32", the front of the seat will be recessed a bit into the bay. I want to build the seat as a frame of 2X4's and 4X4's, then cover that with hardwood -- 1/2" thick on the face and 3/4" thick on the seat. I'll use moldings in two key places -- the transition from the seat to the face, and the transition from the seat to the wall. Here is a plan of the frame, with rough dimensions written in: frame.jpg And here is a plan of what the molding will look like (I have drawn in the window sill molding above the seat here): profile.jpg I am trying to capture the Victorian style of my house in the profile of the seat. I did not draw the doors which will be in the face, because I have not figured out their dimensions yet; there will be two. I am thinking about cutting gingerbread into the doors to echo the house's eaves but I'm not sure about it -- I don't have a scroll saw and it would be a fair amount of work. The baseboard molding in the room, which will be matched along where the face meets the floor, is about 4" high. Update: Here are some comments on the design from WoodCentral folks. They have convinced me to go with hinged holes in the seat to access the storage area, rather than doors in the face -- these will be easier to install and to use. I am nixing the idea of scrollwork in the face, too much work.

posted afternoon of June 21st, 2003: Respond

➳ More posts about Home improvement

|  |

Saturday, July 26th, 2003

Here is an inventory of home improvement projects I want to work on: - Window seat: which I have, ridiculously, still not begun working on; but today I bought some lumber for it and cleaned up my shop, so I have no excuses left...

- Paths in the front yard: I have the slate, I have the tools to cut it; I am hoping to do these paths in the third week of August, when I will be on vacation.

- Path next to the house: Really the same project as the above, I just don't think I have enough slate right now to do it. I want to see how the first path goes before I schedule the others.

- Backyard patio: Again, waiting to see how difficult this slate laying stuff really is.

- Stone at base of side porch: This is going to be pretty complex and I have not really planned yet how it should look.

- New steps for side porch

- Breakfast nook

- Bookcases for Ellen's office: Ellen is breathing down my neck on this so they may come before the breakfast nook.

- Bookcases for living room: I've had an idea for this since we moved here...

- Dining room table: Again, I've had a very clear picture of this kicking around my head for about nine months now.

posted evening of July 26th, 2003: Respond

➳ More posts about Patio

|  |

Sunday, July 27th, 2003

Finally began work (in at least a nominal sense) on my window seat. I measured and cut two story sticks tonight, one for the front of the frame (about 95", square ends) and one for the back (about 48", mitered ends), and marked the alignment between them. I think in the end, using story sticks is actually aiming for a higher degree of precision than is needed in this project; and certainly higher than I am going to attain. There are all kinds of things to deal with along the lines of, the floor is not level, the walls are not square; so it would probably make more sense to just work direct from the tape measure. OTOH story sticks is a really useful technique, one that I am not yet totally familiar with; and I build few enough projects that it is good to practice techniques that I want to develop, even if they do not fit exactly to the current project A "story stick" is just a scrap piece of wood cut to a particular dimension of your project; you use this stick to mark the dimension on the relevant pieces rather than measuring it out on each of them. This helps ensure that pieces which are meant to be sized alike really are, and generally guards against error. In addition, you can mark key points on the story stick, such as mortise locations, to be transfered to the work pieces. The reason the sizes I give above are approximate, is that I marked and cut the sticks from the actual size of the bay window where the seat will be located, rather than with a tape measure.

posted evening of July 27th, 2003: Respond

➳ More posts about Projects

|  |

Monday, July 28th, 2003

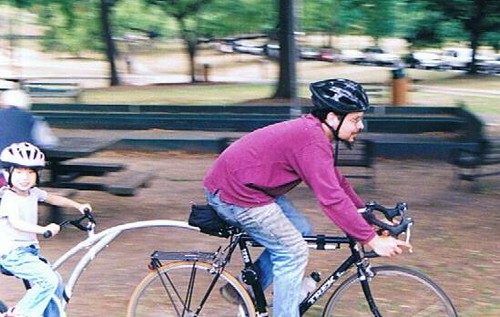

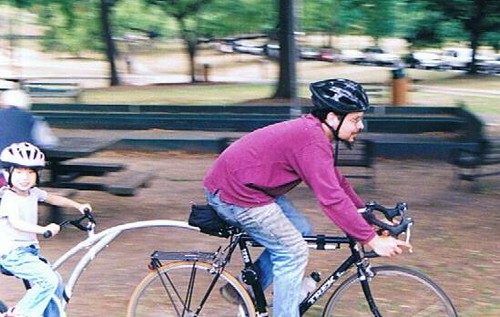

More work on the window seat tonight, cutting out pieces for the rear half of the frame. I got a little worried when I was cutting the verticals, whether my planned seat height of 16" was adequate. Someone from WoodCentral thought it should be higher; and Bill from CJWA advised me to make the seat level with the window sill -- at 16" it is several inches below the window sill. I went back upstairs and looked at the space again, and decided to stay with the planned height. Two free-standing chairs that are in the bay window now are 16" high, and it is very comfortable to sit on them. It also simplifies things a great deal not to have to worry about the window sill. Before dinner, Sylvia was helping me in the wood shop. When I started sawing wood, I offered her to sit on a stool by the bench and watch, but she was not into it. "Can I have a little saw?" caught me a bit off guard -- I generally give her a small, non-dangerous copy of whatever tool I am using; but up till now that has not included tools with sharp edges. Looked around for a bit and then I realized, a mill file is exactly right: it has serrations, makes a rasping noise when you draw it across wood, and is not going to draw blood if you hold it wrong. So I gave it to Sylvia, and she had a good time sawing wood with it until we went up for supper.

posted evening of July 28th, 2003: Respond

➳ More posts about Sylvia

|  |

Thursday, July 31st, 2003

I did some more work on the window seat tonight, finishing off the rear half of the frame. The mortise and tenon joints came out very nice, and without too much effort. I see from my referral log that a lot of people are coming here looking for window seat plans; while I don't have any plans to offer I can tell you it's pretty straightforward design, all you need is a simple frame with two flat pieces of wood on it -- see my first post for the design process and some rough drawings. And if you have questions about it, send me an e-mail -- I'd be glad to help if I can.

posted evening of July 31st, 2003: Respond

|  |

Monday, August 4th, 2003

Motivation is in short supply over here... I eventually got myself down to the basement this evening, looked at the wood and decided I did not want to chop any mortises. It was not such a bad thing though -- I realized I could mark all the joints at one go, which ended up taking about a half hour with all the futzing around I was doing. Tomorrow night I will start chopping. ... Also I got some guitar practice in tonight; I worked out what I think will be a pretty convincing picking pattern for "While my Guitar Gently Weeps."

posted evening of August 4th, 2003: Respond

➳ More posts about Guitar

|  |

Sunday, August 10th, 2003

More progress tonight on the window seat -- it's just inside the bounds of possibility that I will finish it before the end of this month, which would be exciting since we're having a lot of people over on Labor Day, and I would be able to show it off to them. (Assuming it is worthy of being shown off...) Also that would make it a 2-month project from inception to completion, well under my average. On Saturday my time in the shop was spent replacing a broken step on the staircase to our basement -- I cut it from a good stout piece of oak and rabbetted the ends to fit in the existing stringer. Then I helped Sylvia finish building a bed for her Clifford doll, a project we've been working on for about a week. She helped push the plane and helped turn the brace; we nailed on the legs and it was done. Clifford is sleeping in it now, on the floor nearby Sylvia's bed.

posted evening of August 10th, 2003: Respond

|  |

Saturday, August 23rd, 2003

We're back in town -- the week was a flurry of fun activity. I would like to write a long post about it but I don't know whether I will or not -- I have other stuff to do this week like building a path in my yard and finishing the window seat. If you are dying to know about it send me a note and I will give that a higher priority.

posted evening of August 23rd, 2003: Respond

|  |

Sunday, September 7th, 2003

A very productive weekend... The window seat frame is installed; the seat would be on except I found out home depot does not carry the plywood I am looking for. There is a lumber yard in Union which I will try next Saturday. Mike R. came over Friday to help me with the baseboard and the electrical outlet, which I wanted to move to the front of the seat; but the baseboard proved impossible to remove from the wall. So I left it in place and put the frame in front of it. The molding has changed a lot; rather than a crown molding I have decided to use a window apron molding, which is more natural in the context and will fit in nicely with the window aprons behind the seat. I will be building it out of 6 pieces of wood and it may not be ready immediately. We had a really nice jam session this afternoon, playing about 8 songs which is about double what we normally get to, and they were a lot of fun. With Jim, I came up with a new arrangement of House of the Rising Sun which really sounds like a distinctively new sound for that song, riffing on Dylan's version but quite different. Sylvia came (of her own accord) and stayed for about two hours of jamming -- quite breathtaking to me since we were not changing our jam much at all to accomodate her in it. (Before it started, Greg saw a hawk eating a squirrel in the lower branches of a tree on the property 3 doors down from Bob's place, so we went down there to watch it for 15 minutes.) Afterwards we had a cookout, for which Sylvia came back to join us.

posted evening of September 7th, 2003: Respond

|  |

Sunday, September 14th, 2003

Yesterday I put the plywood shell onto the window seat and began the process of filling in molding around it. This consists mainly of: the baseboard, the sill, and the apron. I spent this morning working on the baseboard, and it looks pretty nice. Our house has large moldings; the baseboard around the seat is about 6" tall and is made up of at least 4 separate pieces of wood, which I will refer to as base, head, cap, and toe. (Some of these may actually be made up of more than one piece but I will assume not.) The base is a rectangular piece 1" deep and 4 3/8" tall, with a 1/4" bevel at the top. The head is a rectangular piece 3/4" deep and 7/8" tall which rides on top of the base -- the bevel in the base meets the depth of the head. The cap is a sort of teardrop-shaped piece about an inch tall; and the toe is a 3/4" quarter-round piece which makes the transition from the base to the floor. The first thing I did was to cut the base. The main work of this was planing the board I had, 1 3/16" thick, to 1" thickness; once I had that I had to figure out how to cope it to get the bevel to meet the bevels of the baseboard around the seat. Basically I did a straight cut 1/4" inside the end of the board that stopped 1/4" from the top, and then chopped an angle from the corner of the board to the end of the cut. It came out pretty well -- the coping is not perfect but it is well within the abilities of caulk and spackle to make it look just right. I attached this to the front of the seat with screws to hold it tight, and then nailed the head piece to it. (The head piece is the simplest, just a straight rectangular piece.) Next came the toe, which I am quite happy with. I had taken the toe pieces out from behind the seat and used these, which I had to cope to make them meet up properly. The last thing is going to be the cap, which I also took out from behind the seat -- I am a bit nervous about whether it is going to work though, as in the original baseboard the cap is attached to the head with a rabbett, which I mostly broke when I was prying the cap off. I am going to plane the base of the cap pieces off flush and see how it works.

posted evening of September 14th, 2003: Respond

| More posts about Window seat

Archives  | |

|

Drop me a line! or, sign my Guestbook.

•

Check out Ellen's writing at Patch.com.

| |